The Engine (Page 2 of 2)

Journal Cover Page Page 1

(To navigate the photo journal, click on the tabs on the right and the links at the top or bottom of this page.)

Cowling |

|

|

|

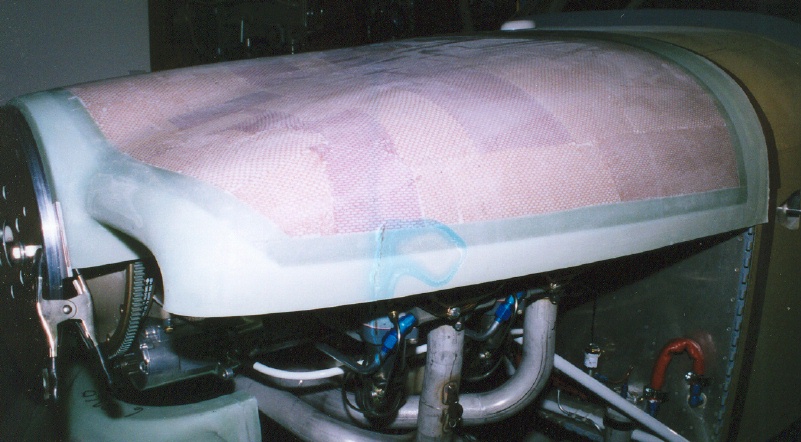

| Now the real fun begins. Fitting the cowling. Here is the upper half before any trimming. On the left side if the picture, you can see the temporary prop spinner backplate and a spacer in place to position it on the airframe. The right side of the picture shows the cowl half overlapping the fuselage. This will be scribbled and trimmed back to fit. | |

|

|

| This picture shows the method I used to fit the upper cowl so it is spaced sufficiently behind the spinner. The problem I had to overcome was that the I had to fit the cowl before receiving the propeller and its spinner. To make matters worse the clearance given by Van's and the engine builder did not agree. Here, I'm using the stock spinner plate that came in the kit and a one eighth inch spacer shim. I don't recommend this approach. My results were not very precise. | |

|

|

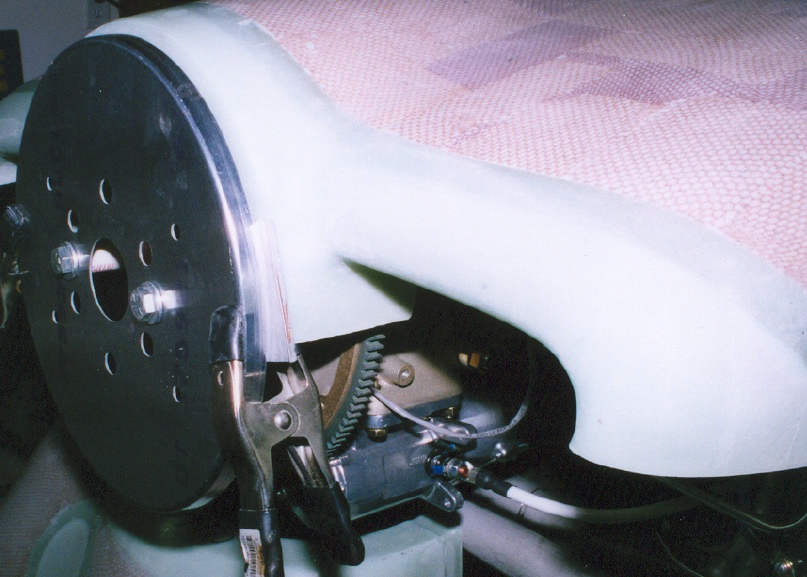

| Here, the cowl halves have been fitted to the fuselage at the firewall; but, still need to be attached to each other with piano hinge segments. | |

|

|

| Here is a view from the right side at the same stage of completion as the picture above. Some shaping work will be required later to make the top and bottom cowl halves mate together precisely. | |

|

|

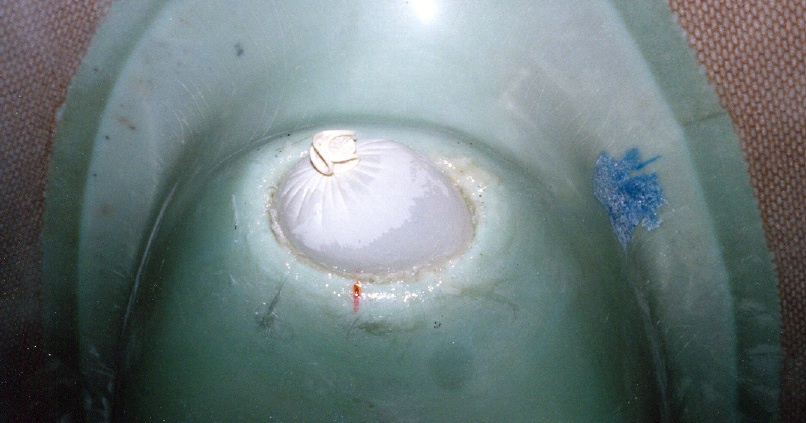

| It is necessary to do a little fiber glass lay up to mate the intake on the lower cowl (shown here) to the carburetor air box hanging from the bottom of the engine. | |

|

|

| This is the inside view of the air intake on the lower cowl. With no balloons available in the shop, a latex glove did the job of holding the epoxy in place while it cured. I removed the blue foam later and shaped the fiber glass lay up to fit the filtered air box intake. | |

Cooling Baffling |

|

|

|

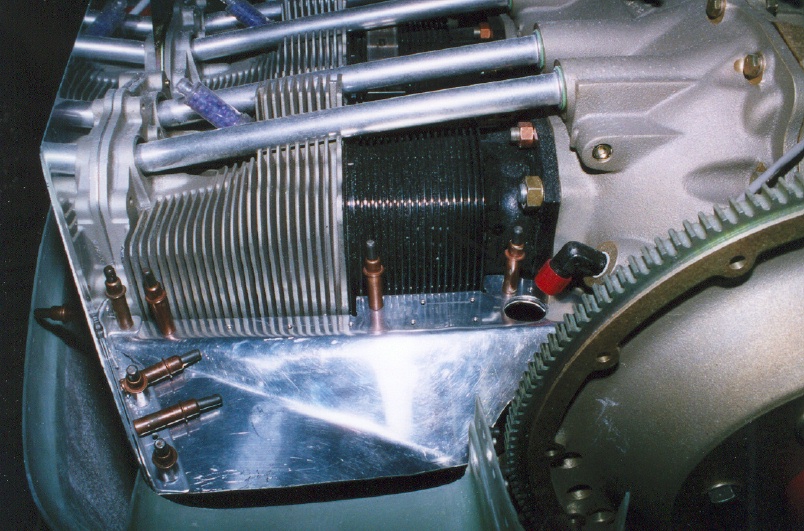

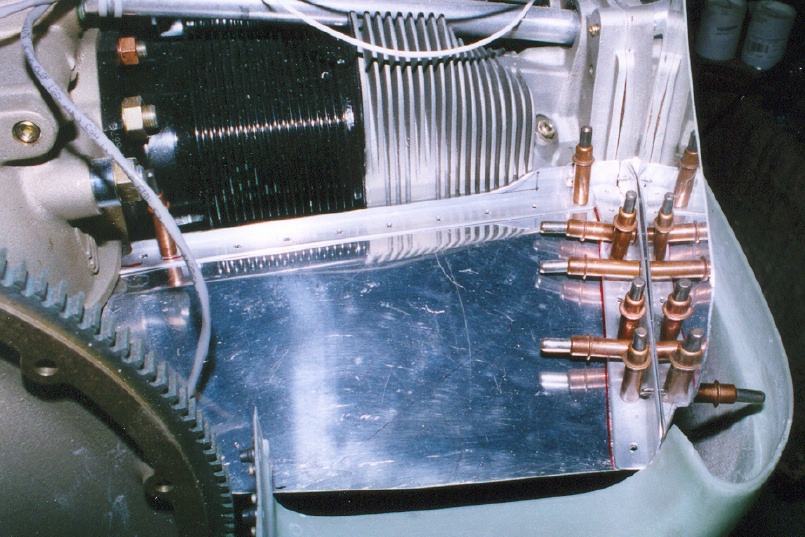

| This the right front cooling baffling. The baffling kit is a definite must. Its hard enough to get all the pieces to fit to the engine without having to bend them to their basic shapes as well. | |

|

|

| Fitting, trimming, drilling, and fabricating the left front cooling baffling parts. | |

|

|

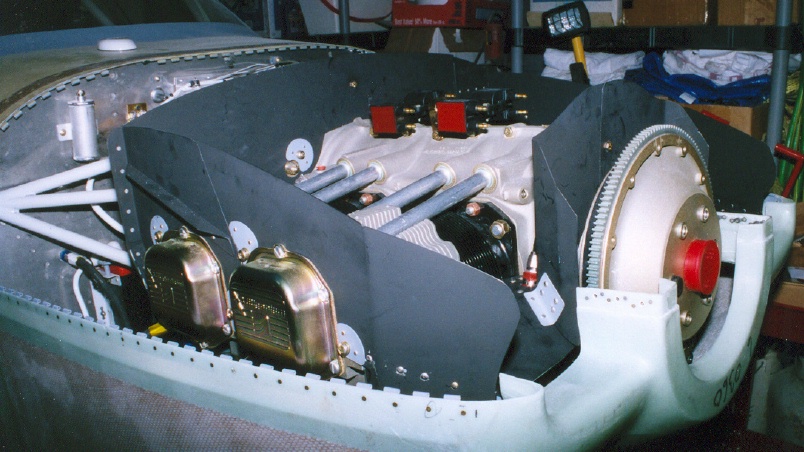

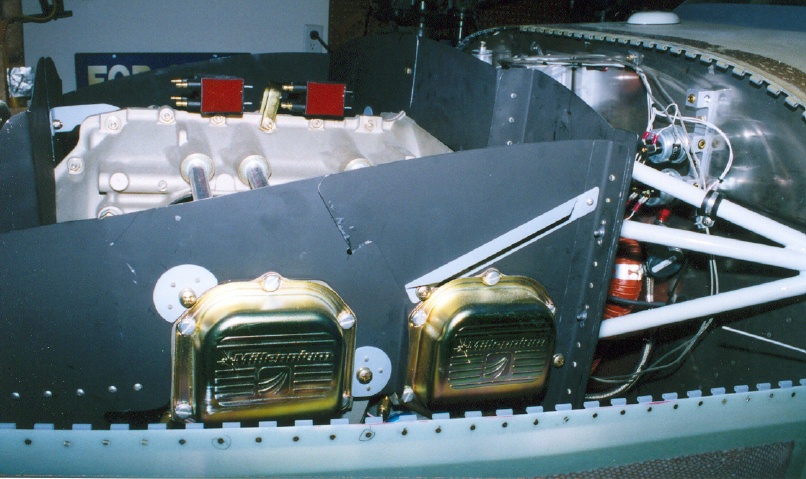

| All the baffling parts are painted and fitted and secured in place. The still need to be trimmed to clear the upper cowl and the baffle seal needs to be added. | |

|

|

| This hole in the left rear of the baffling is where the oil cooler will attach. | |

|

|

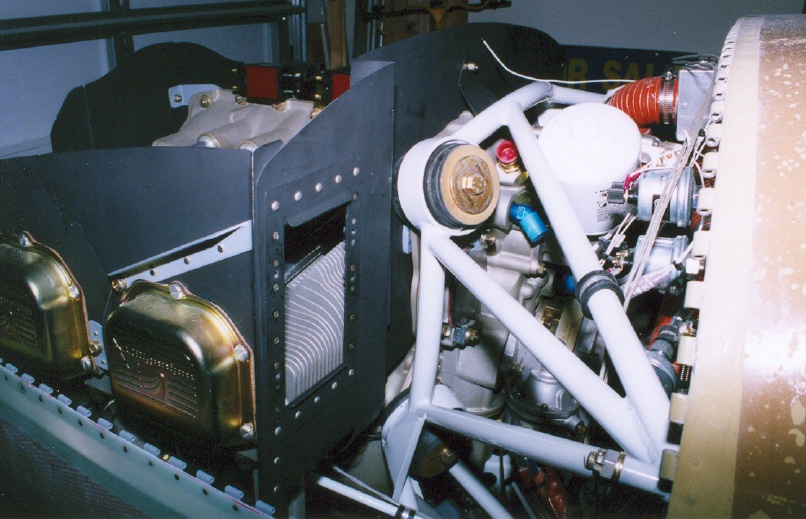

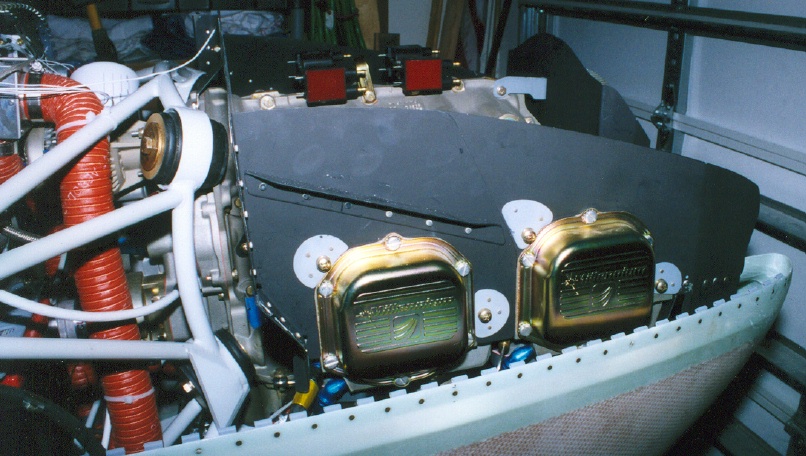

| A view from the left side. You can also see the electronic ignition coils mounted on top of the engine. | |

|

|

| A clear shot from the right side. | |

|

|

| To smooth the air flow into the engine for efficient cooling and minimize drag, these two parts are bonded to the inside of the upper cowl. I drilled few sacrificial "tooling holes" so the cleco clamps can be used to hold the assembly in place while the epoxy cures. Later these holes will be filled as part of the surface finishing and paint prep. |