The Engine (Page 1 of 2)

Journal Cover Page Page 2

(To navigate the photo journal, click on the tabs on the right and the links at the top or bottom of this page.)

Oil Door |

|

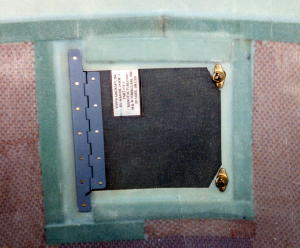

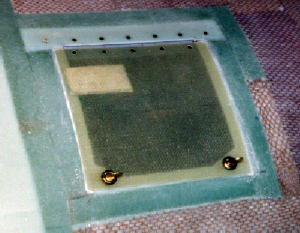

| Oil Door installed on the top cowling. This view is from the under side. |  |

|

Here is what it looks like from the top. |

| It opens. I guess that means it works. |  |

Firewall Forward |

|

|

|

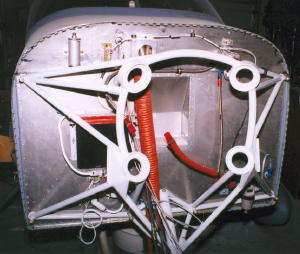

| This is the remote engine instrument sensor bracket. It will hold the oil and fuel pressure transducer. | |

|

More items installed on the firewall, including the oil and fuel pressure lines. |

|

|

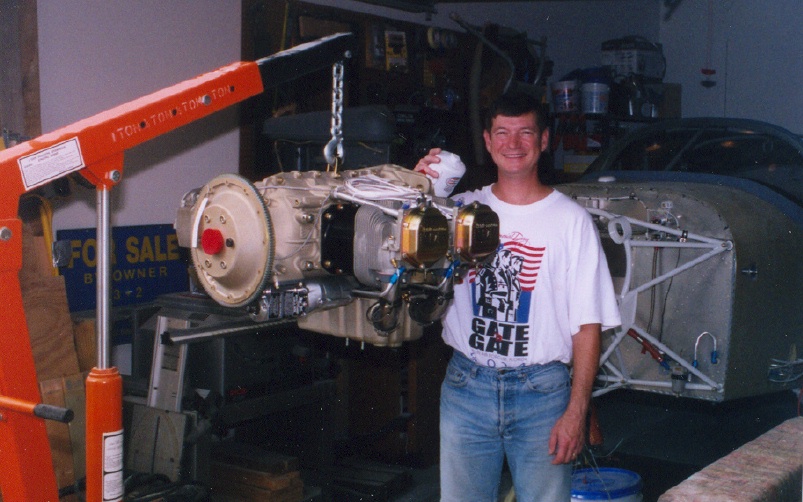

| Finally, the engine has arrived. Yes, it comes shipped in a cardboard box. Don't worry, there is a lot of expanded foam inside to keep it safe. | |

|

|

| The engine is Superior Air Parts. It's an XP-360 kit built and tested for me by Eagle Engines in Redding, CA. | |

|

|

| We used the engine hoist to lift it out of the crate and the bed of the truck. | |

|

|

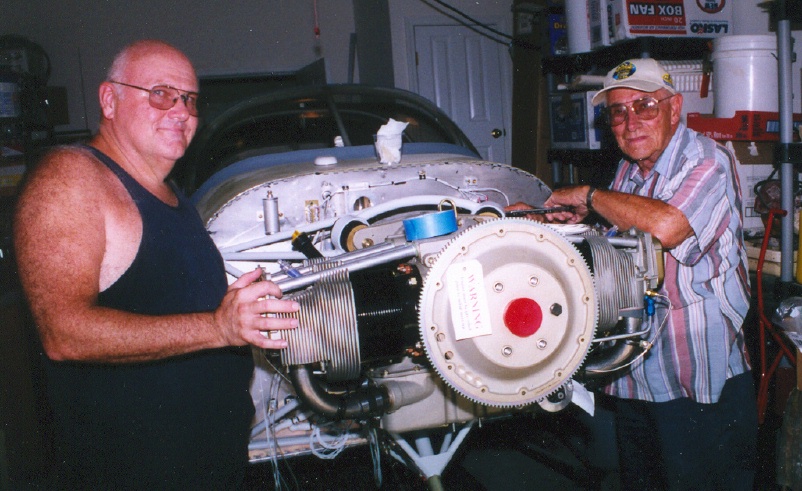

| A little help from RV-4 builder, Bob Hankins, sure made maneuvering the engine a lot easier. | |

|

|

| Also, keeping me from making any really stupid mistakes is veteran RV-6 builder Cliff Nunnery on the right. | |

| The plane had been in the garage nose first up to this point. But, to hang the engine, I needed a little more space. So, I turned it around. Here is a view from the kitchen looking into the garage. |  |

|

|

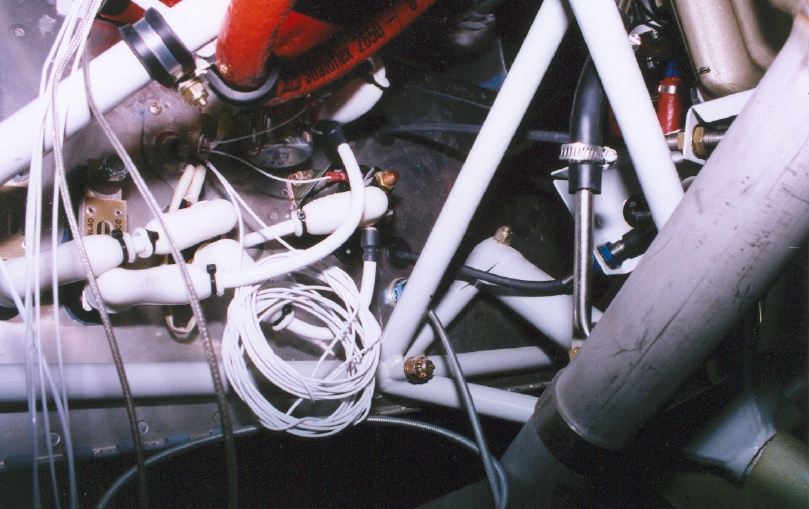

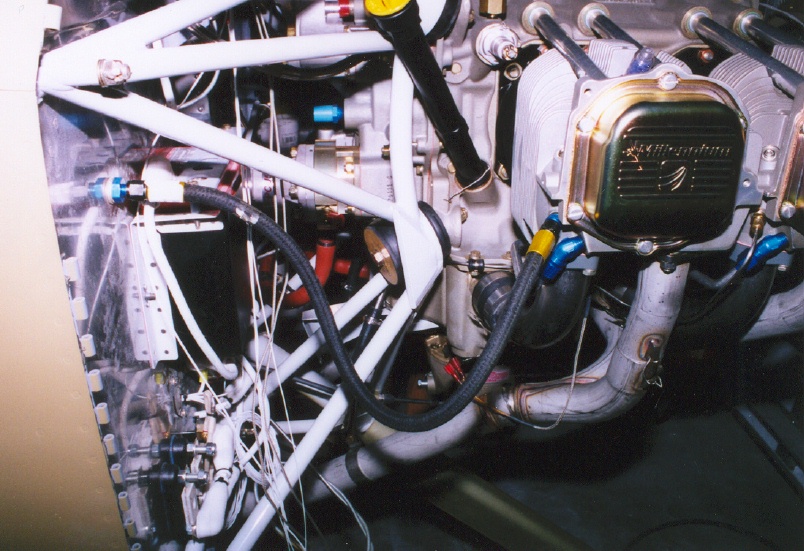

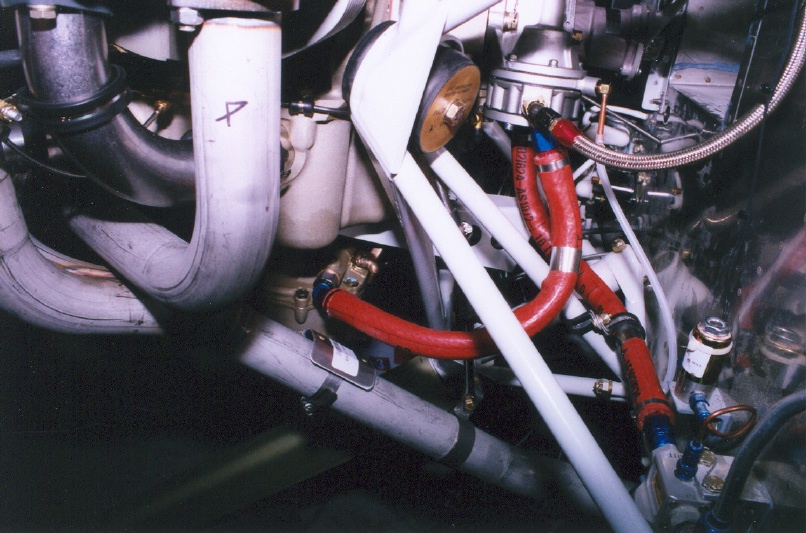

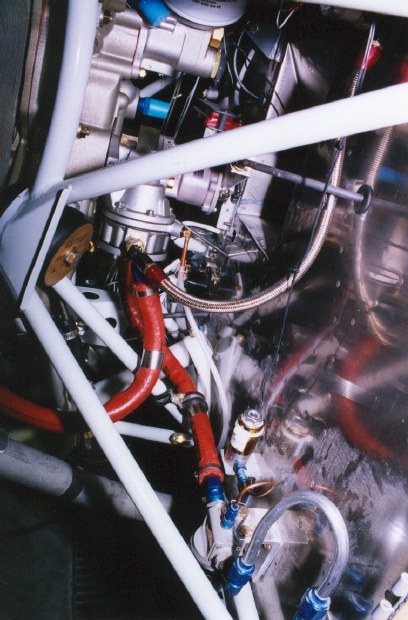

| Pictures start to jump around a bit from here on. This picture is taken from the right side, looking at the lower firewall area. The white tubes are the engine mount. The large tube on the right is the exhaust pipe. The red hose at the top of the picture is the oil return line from the prop governor to the front of the engine. | |

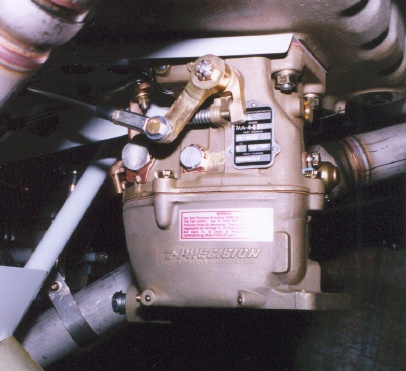

| Here is a shot of the carburetor from the right side. It's an up draft type, hanging from the bottom of the engine with the air intake at the bottom. |  |

|

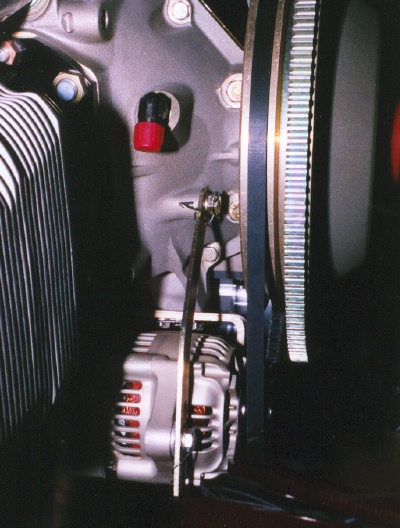

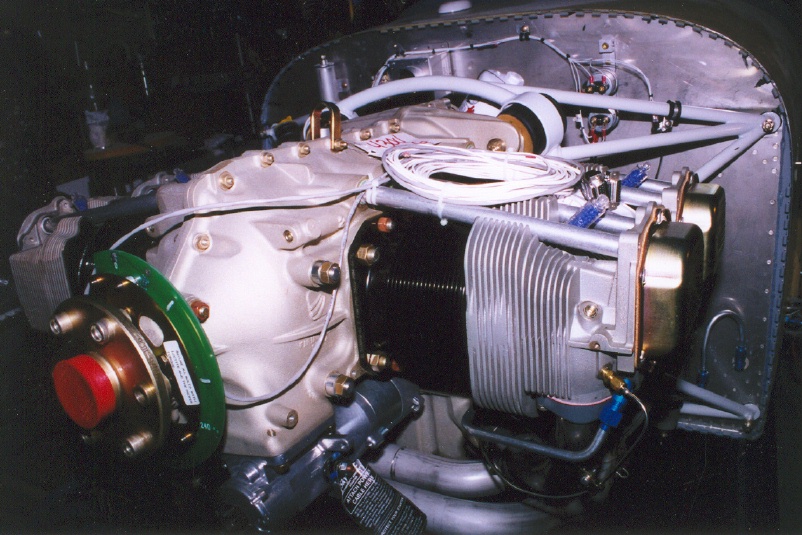

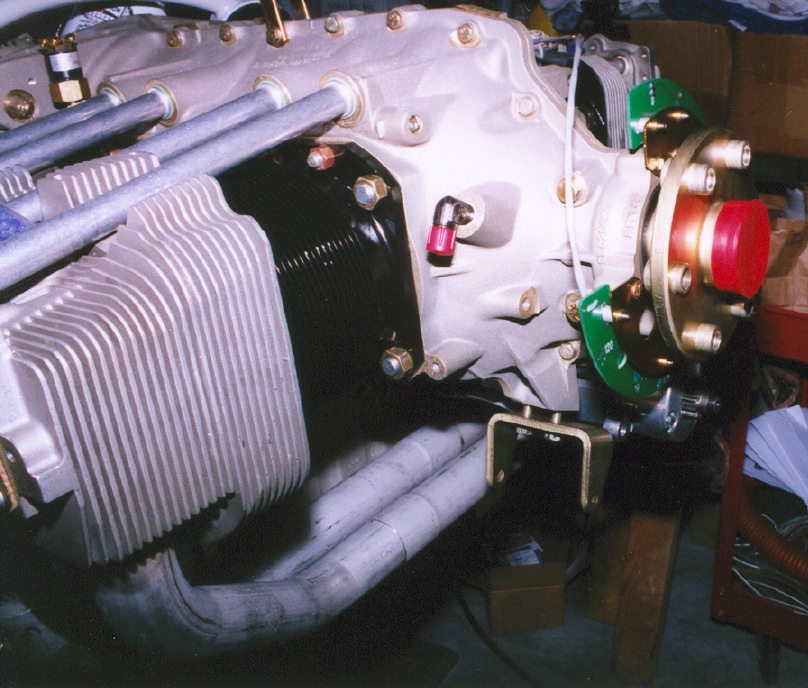

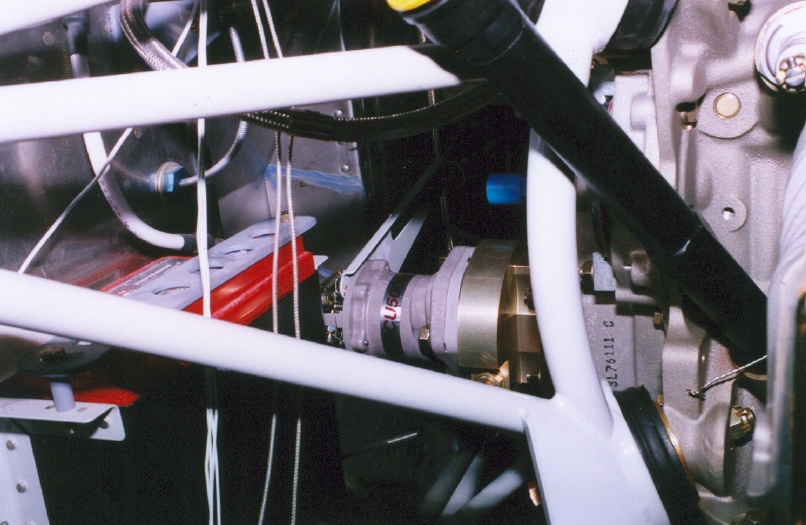

This is the front of the engine from the right side. The red plastic plug is on a fitting for the return oil line from the prop governor. The main alternator is installed on its bracket and the alternator belt is in place around the fly wheel. |

|

|

| Here is a shot of the engine from the left front. With the fly wheel removed, you can see the crank sensor for the electronic ignition. It's the green card at the front of the engine with the coils of wire connected to it. Where the spark plugs should be are some plastic dessicant plugs. If the blue beads turn red, they are saturated with water and won't do any more good until dried or replaced. The starter is in the lower part of the picture. | |

|

|

| This picture is taken from the right front with the fly wheel removed. in the upper left, you can see the oil pressure switch for the HOBBS meter. The alternator is not in place, but its bracket is. | |

|

|

| This is the right rear of the engine. The dip stick tube is in place and the black hose you see in the foreground carries the manifold pressure to the manifold pressure gauge and the electronic ignition computers. | |

|

|

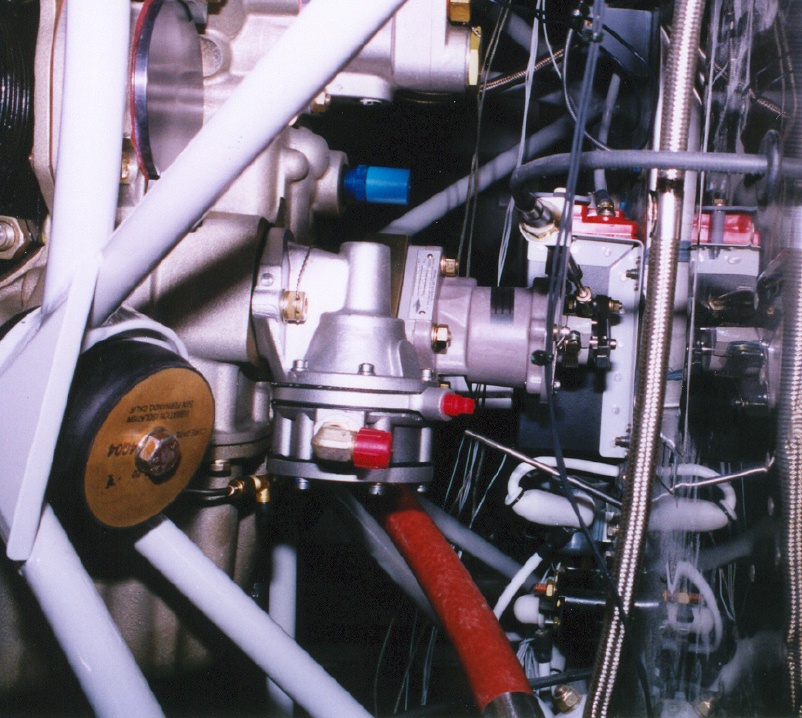

| Here is a picture of the lower portion of the left rear of the engine. You can see most of the fuel system in this picture. The fuel comes through the firewall via a line that is connected to the left side of the gascollator at the lower right. Then, it travels to the fuel pump in the upper right of the picture. You can also see the small tube coming out of the top of the gascollator to the fuel primer. Coming out of the fuel pump is a line going to the carburetor and one going up to the fuel pressure gauge sender out of the picture at the top right corner. | |

|

Another shot of the left side from a slightly different angle. |

|

|

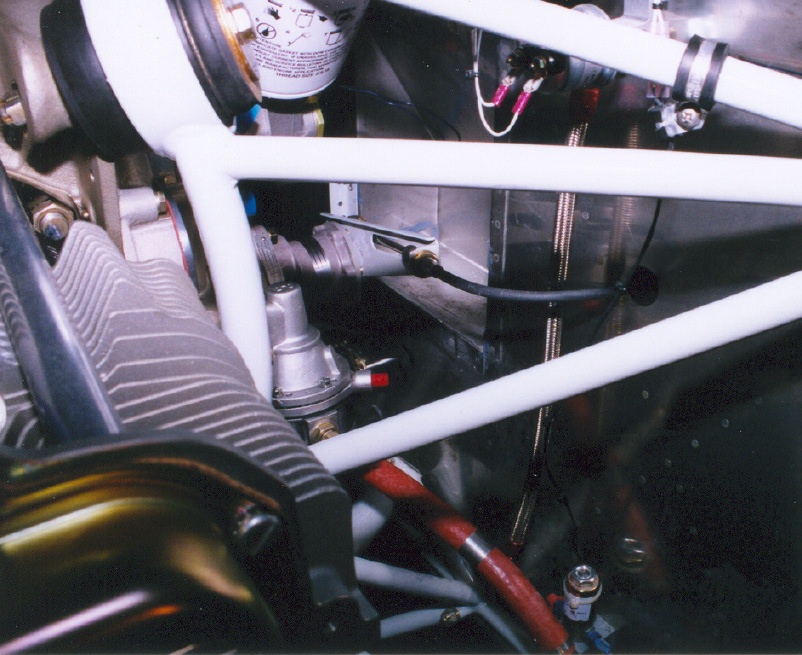

| In this picture you can just see the prop control cable coming out of the firewall and curving over to its bracket on the back of the prop governor. | |

|

|

| The fuel pump and prop governor are visible here from the left side. | |

|

|

| Here is what the prop governor looks like from the right side looking down. The battery you see in its bracket on the firewall is the backup battery. The main battery is in the cockpit on the floor between the rudder pedals. | |

|

|

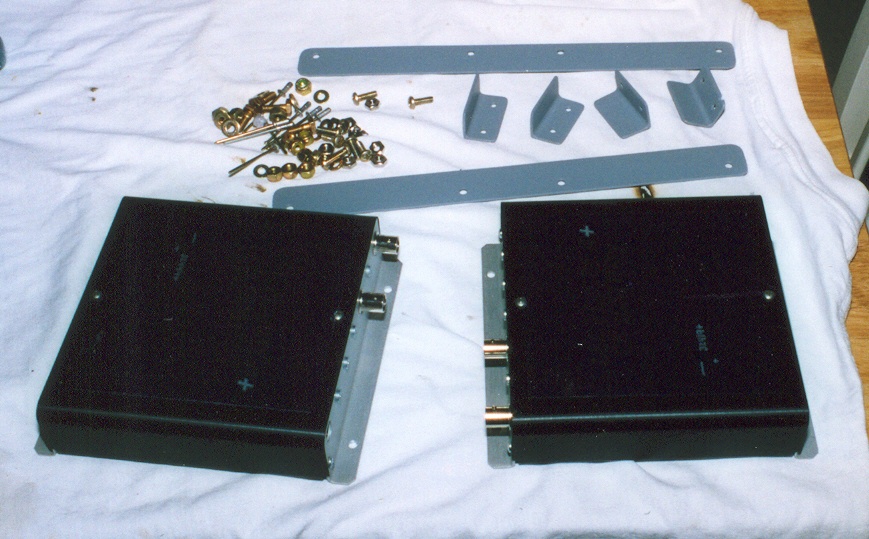

| Here are the electronic ignition computers, one for each set of spark plugs. Also shown are the pieces I made to hang them on the cockpit side of the firewall and the hardware. | |

|

|

| I coupled them together on two aluminum straps. The angles you see get riveted to the firewall stiffeners and then the straps are bolted to the angle brackets. | |

|

|

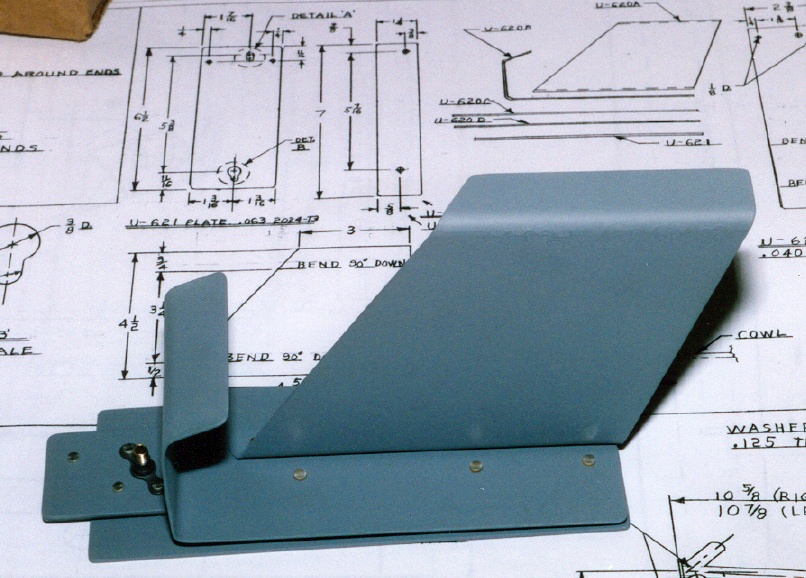

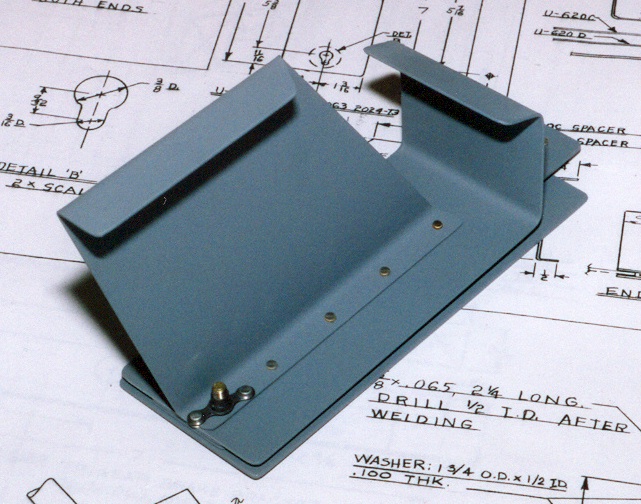

| The next series of pictures is different angles of the lower cowl bracket. | |

|

|

| It's a little hard to visualize exactly how this is supposed to go together at first. | |

|

|

| During installation on the airplane, I had to shim it quit a bit at the engine mount attach point to get it to fit correctly. | |

|

|

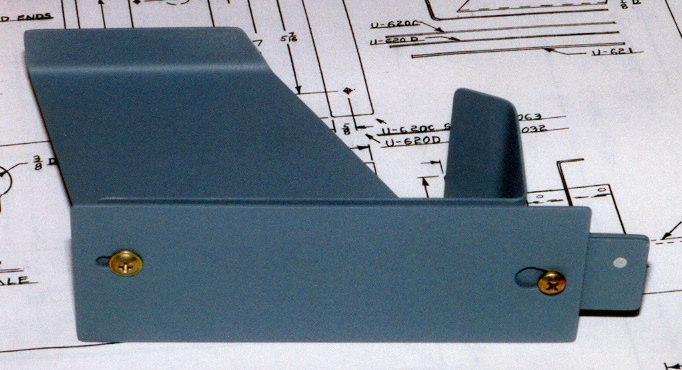

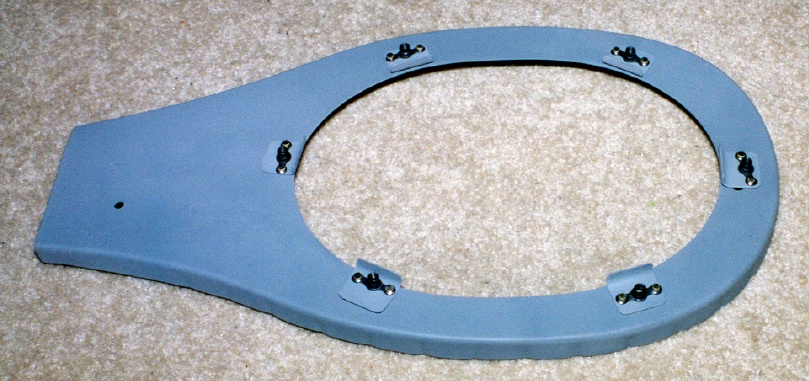

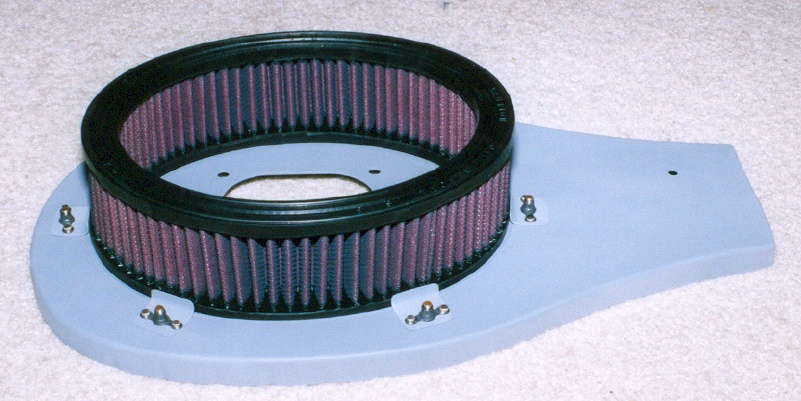

| Here are a couple of shots of the carburetor air box assembly that hold the air filter and directs the air into the carburetor | |

|

|

| It's upside down in this picture. The plate is bolted to the bottom of the carburetor and riveted to a fiber glass enclosure. | |